05 Top Tips to Resolve Industrial Furnace Problems

Regular furnace maintenance is vital for optimal performance and safety. Start by checking and cleaning or replacing the air filter every 30 days to prevent airflow issues and potential fire hazards. Afterward, inspect the thermostat, ensuring it’s set to “heat” and adjusting the temperature accordingly. Dust off electromechanical thermostats and prevent false readings by checking their location.

Additionally, if power issues arise, inspect the furnace switch and electrical panel, resetting breakers or replacing fuses as needed. A healthy furnace flame, primarily blue, indicates safe fuel burning; contact a professional for other colors.

Lastly, follow your owner’s manual to relight the pilot carefully, ensuring the gas is off for 10-15 minutes, and evacuate if a gas smell persists.

This blog is your industrial furnace troubleshooting guide to ensure your furnace operates smoothly, preventing potential breakdowns and safety hazards.

Industrial Furnace Troubleshooting Guide

Check the Furnace Filter

The air filter is the first line of defense against dirt and dust. Over time, a clogged filter can impede airflow, worsen indoor air quality, and even pose a fire hazard. To maintain optimal performance, check and clean or replace your air filter every 30 days. Remember to turn off the thermostat and furnace switch before conducting any maintenance work.

Thermostat Check

After confirming the cleanliness of your furnace filter, inspect the thermostat. Ensure it’s set to “heat” and adjust the temperature at least five degrees higher than the current room temperature. Replace batteries if needed and dust off electromechanical thermostats gently. Check the thermostat’s location to prevent false readings from external heat sources.

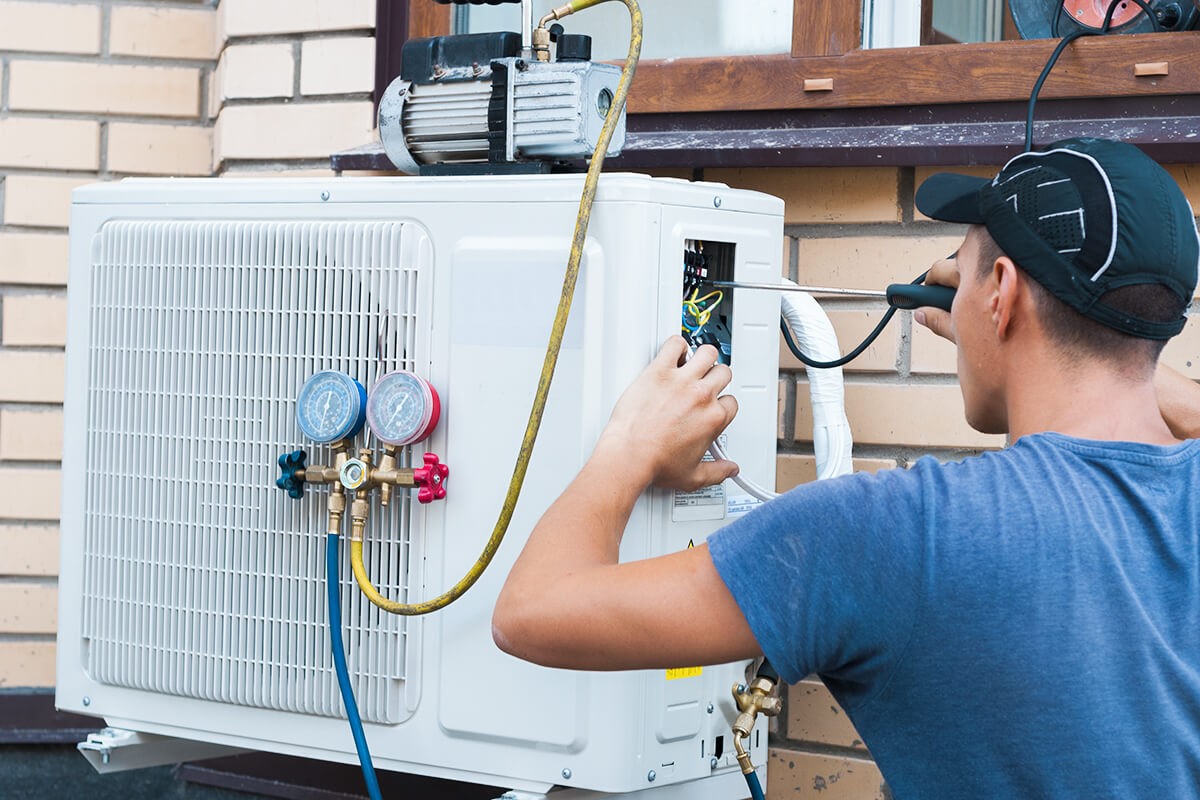

Furnace Switch and Electrical Panel Inspection

If the filter and thermostat are in order, power issues could be the culprit. Check the furnace switch near the furnace and ensure it’s turned on. If needed, head to the electrical panel. Make sure the power is on at the breaker box or fuse box. Reset the breaker or replace a blown fuse with the same size and type. Exercise caution, ensuring your hands and feet are dry during this process.

Inspect the Furnace Flame

A healthy furnace flame should be primarily blue, indicating safe and efficient fuel burning. Any other color suggests an issue requiring professional attention. Never attempt to fix the furnace flame color on your own; contact a professional promptly for HVAC repair in Blairsville, GA.

Pilot Light and Gas Valve Check

If the furnace flame is out, follow your owner’s manual to relight the pilot carefully. Turn off the gas for 10-15 minutes before attempting to relight. If a gas smell persists, evacuate immediately and contact the gas company and fire department from a safe distance.

Final Thoughts

By following this industrial furnace troubleshooting guide, you can ensure warmth, indoor air quality, and the overall efficiency of your furnace. If in doubt or if issues persist, always seek professional assistance for a thorough inspection and necessary repairs.

Lastly, if you’re looking for a professional industrial furnace or HVAC repair in Blairsville, GA, we would advise you to opt for a leading HVAC repair company like Wayne’s Heating & AC.

Read More: Top 5 Residential HVAC Companies for Quality Comfort Solutions

FAQs

Q1: What should I do if my industrial furnace is making unusual noises?

A1: Unusual noises in an industrial furnace may indicate issues with the blower motor, bearings, or other mechanical components. Turn off the furnace immediately and contact a qualified technician to inspect and address the source of the noise.

Q2: How can I troubleshoot uneven heating in my industrial furnace?

A2: Uneven heating may be caused by issues with the distribution system, such as blocked vents or ductwork. Ensure proper airflow by checking and clearing any obstructions. If the problem persists, consult with a heating professional to assess and resolve the issue.

Q3: What are the common causes of frequent industrial furnace breakdowns?

A3: Common causes of frequent breakdowns include lack of regular maintenance, dirty or clogged filters, and worn-out components. Implementing a routine maintenance schedule, replacing filters, and addressing issues promptly can help prevent frequent breakdowns and improve overall furnace performance to avoid getting heating and air conditioning repair services.