Custom Peptide Synthesis: Tailored Solutions For Your Research Needs

The biochemist field has experienced a tremendous shift in recent years due to technological advancements. Biochemists can now produce custom compounds such as antibodies, proteins, and peptides. The improved purification methods also help enhance these compounds’ quality, guaranteeing better results.

Custom peptide synthesis is one of the processes enhanced by improved technology. How much do you know about custom peptide synthesis? The following article will take you through some of the essential things you ought to know about peptide synthesis.

What is Custom Peptide Synthesis?

Custom peptide synthesis produces synthetic peptides in biotechnology, pharmacology, molecular medicine, and biochemistry research laboratories. Synthetic peptides are also essential components in the production of custom proteins and custom antibodies. They are also effective tools in biomedical laboratories.

Synthetic oligopeptides are extensively used to develop binding assays, study structure-function analysis such as protein-protein interfaces, and study antagonists. For these reasons, custom peptide synthesis is an essential process. As a researcher, you can seek peptide synthesis services from a laboratory or produce yours through simple procedures.

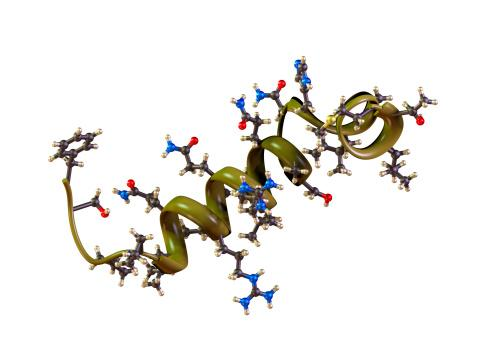

In custom peptide synthesis, peptide bonds are essential. They are covalent chemical bonds that help to bond the amino acids. The various amino acids are coupled with chains through a process known as condensation. The resulting bonding and reaction is the formation of the dipeptide. However, for the condensation process to happen, one amino acid must react with an amino group of a different amino acid molecule. Also, the reaction should be exposed to a high energy level, whether the bond is being formed chemically or organically. The whole reaction is dehydration since it gives water as a by-product.

Custom peptide quality is measured in terms of the maximum length produced. Sometimes, if not always, it’s hard to produce long peptides which have high quality. Therefore, peptides must undergo a thorough analysis known as the Quality Control procedure.

Methods Used In Custom Peptide Synthesis

Three standard methods produce custom peptides: solid-phase peptide synthesis, liquid-based phase synthesis, and solid-phase synthetic method.

Solid-Phase Peptide Synthesis (SPPS)

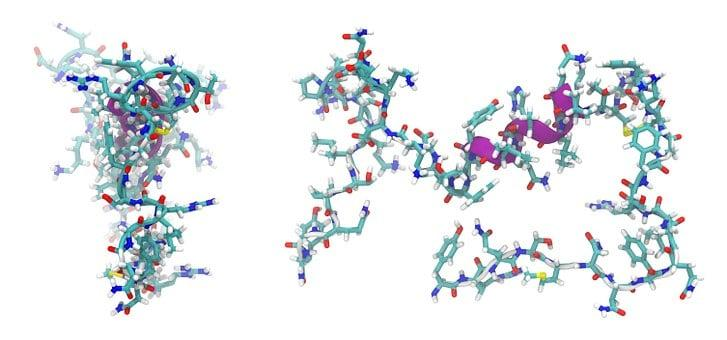

Solid-phase peptide synthesis is the most established method used in peptide production. This method allows a robust and rapid collection of peptide chains using successive reactions in a microscopically insoluble solvent by the amino acids derivatives. This process is usually supported by beaded resin.

Solid-phase peptide synthesis makes it possible to produce high-quality peptides in large quantities. This has helped to bring a paradigm shift in research fields and discover an array of vaccines and medicinal agents. In addition, this method helps to produce pure peptides essential in all research.

Moreover, the solid phase peptide synthesis method has been improved using modern technology to increase its efficiency in peptide synthesis. A good example is how complex purification has been simplified to simple filtration from the long and tedious crystallization at the end of the synthesis process. Due to these advancements, most researchers prefer solid-phase peptide synthesis for producing small-scale and large-scale peptides.

Classical Solid Phase Synthetic Method (SPS)

The solid phase synthetic method was the first used method in peptide synthesis. It was later advanced to solid-phase peptide synthesis. Unlike the SPPS method, which involves a chain of amino acids, the SPS method couples a single amino acid in a given solution. This method is ideal for the production of long peptides. To get long peptides, fragments of short peptides are first synthesized and then joined to give long peptides.

The primary advantage of the SPS method in peptide synthesis is that you can deprotect the immediate product and purify them instantly to get the final pure peptide. Some peptides that can be synthesized using this method include oxytocin, porcine gastrin, and human insulin. Though this method is cheaper and affordable in peptide synthesis, the long and tedious process can be time-consuming, which is the main disadvantage of this method.

Peptide Purification

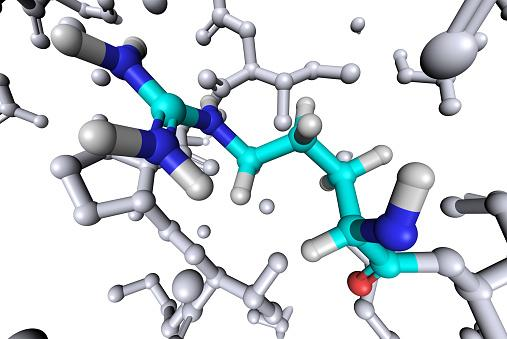

Peptide purification is a necessary process when it comes to peptide synthesis. It’s usually the last stage in peptide synthesis. This process helps to eliminate any unwanted element/component or side reactions that may have accumulated or remained in the final peptide. Purification helps to increase the quality and purity of the desired peptide.

The purification method used in peptide synthesis is primarily determined by the production process and type of components used. Various methods are used in peptide purification, such as RP-HPLC chromatography, flash chromatography, hydrophobic interaction, hydrophilic interaction chromatography, ion-exchange chromatography, and hydrophilic interaction chromatography.

However, all purification methods may require a significant amount of solvent, and sometimes they can give low yields. Also, the process may be extended and repetitive, increasing production costs. Nevertheless, the process is worthwhile if you need high-quality and pure peptides with no impurities. You can also skip the purification process by using the solid-phase synthetic method.

Wrapping Up

Peptide Synthesis is an important process in the biochemist field. It’s the best solution for all your biochemist research. With technological advancement, the process is now simple and quick. Custom synthesis is an essential tool for studying biological structures, the development of enzyme inhibitors, and other therapeutic and medicinal agents.

In addition, custom peptide synthesis services cost may differ depending on the desired peptides, the process used, and the length of the final peptides. The purification process also helps determine the price of peptide custom synthesis services. When seeking such services, always go for reliable manufacturers. You can review the process and applied components before requesting the services.