Why the slitting coil packing line in important for slitting coil production

The steel coil packing line is an essential component of a slitting coil production process, ensuring that coils are packaged efficiently, consistently, and safely, and protecting them during transportation and handling. It is important for slitting coil production for several reasons:

Protection during transportation: The steel coils produced in a slitting line are often transported to other locations for further processing or use. Packing the coils properly ensures that they are protected during transportation and handling, reducing the risk of damage and ensuring that they arrive in good condition.

Efficient packaging: Steel coils can be quite heavy and unwieldy, making them difficult to handle and package manually. A steel coil packing line automates the process, making it faster and more efficient, and reducing the need for manual labor.

Consistency in packaging: An automated packing line ensures that each coil is packaged consistently and correctly, which is important for maintaining product quality and reducing waste.

Improved safety: Steel coils can be dangerous to handle, especially when they are not packaged properly. A steel coil packing line improves safety by reducing the need for manual handling of heavy and awkward coils.

Customization options: A steel coil packing line can be customized to meet the specific needs of a slitting line. For example, it can be designed to handle coils of different sizes and weights, or to apply different types of packaging materials.

- The machines and function in the slitting steel coil packaging line

- Automatic coil car for steel coil transfer from slitting line to the packing line.

An automatic coil car is a machine used to transfer steel coils from a slitting line to a packing line in a manufacturing facility. The coil car operates automatically and is designed to improve the efficiency of the packaging process by reducing the need for manual handling.

The coil car typically consists of a frame that supports a hydraulic lifting mechanism, which can move the steel coil from the slitting line to the packing line. The lifting mechanism is designed to hold the coil securely during transport and to release it safely at the packing line.

The automatic coil car is an essential component of a packaging line, as it helps to reduce the risk of injuries and accidents caused by manual handling of heavy steel coils. It also helps to improve productivity by reducing downtime and minimizing the need for manual intervention.

In addition to the automatic coil car, a typical packaging line may include other machines and functions such as coil tilters, banding machines, stretch wrap machines, labeling machines, and conveyor systems. These machines work together to efficiently package and prepare steel coils for shipping and transport.

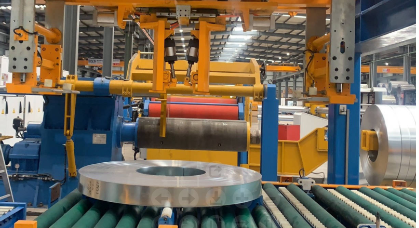

Automatic turnstile and down ender for steel coil picking up one by one and 90 degree turning

An automatic turnstile and down ender are machines used in a steel coil handling system to pick up individual steel coils and rotate them 90 degrees for further processing or transport. The automatic turnstile and down ender are critical components of a steel coil handling system, helping to ensure the safe and efficient handling of these heavy and potentially dangerous materials.

The turnstile is a mechanical device that is designed to grab a steel coil and rotate it 90 degrees so that it is in the correct orientation for processing or transport. The down ender is a device that is used to safely lower the steel coil from an upright position to a horizontal position. This ensures that the steel coil is properly supported and does not roll or tip over during transport.

Together, the turnstile and down ender allow for the safe and efficient handling of steel coils, reducing the risk of injury to workers and damage to the coils. The machines are typically automated, which helps to increase productivity and reduce the need for manual handling.

In a steel coil handling system, the turnstile and down ender are typically located at the beginning of the line, where they pick up coils from a storage area and transport them to the processing area. The coils are then typically transported along a conveyor system to other machines for further processing, such as slitting or stamping.

Automatic steel coil wrapping machine

An automatic steel coil wrapping machine is a specialized piece of equipment used in industrial settings to wrap steel coils with a protective layer of material, typically stretch film or paper. The machine operates automatically and is designed to improve the efficiency and accuracy of the wrapping process while reducing the need for manual labor.

The wrapping process begins with the placement of a steel coil onto the machine’s rotating platform, which is typically powered by an electric motor. Once the coil is secured in place, the machine will begin to wrap it with the chosen protective material. This can be done in a variety of ways, such as by spinning the coil while a pre-determined amount of material is dispensed, or by moving the dispensing mechanism around the coil in a controlled manner.

Automatic steel coil wrapping machines are capable of wrapping coils of various sizes and weights, and can be customized to suit specific industry needs. They are commonly used in industries such as steel production, metal fabrication, and transportation, where the protection of steel coils during shipping and storage is crucial.

There are some additional equipment such as conveyors, tilters, and packaging material dispensers. These machines work together to create a streamlined, automated system for wrapping and protecting steel coils, resulting in improved productivity, efficiency, and safety.

Automatic steel coil strapping machine

An automatic steel coil strapping machine is a specialized piece of equipment used in industrial settings to secure steel coils with straps or bands. The machine operates automatically and is designed to improve the efficiency and accuracy of the strapping process while reducing the need for manual labor.

The strapping process begins with the placement of a steel coil onto the machine’s conveyor system. The machine then automatically feeds the steel coil through the strapping head, which applies the strapping material and secures it in place using a variety of methods, such as heat welding or mechanical fastening.

Automatic steel coil strapping machines are capable of strapping coils of various sizes and weights, and can be customized to suit specific industry needs. They are commonly used in industries such as steel production, metal fabrication, and transportation, where the secure strapping of steel coils during shipping and storage is crucial.

A typical steel coil strapping system may include additional equipment such as conveyors, coil tilters, and packaging material dispensers. These machines work together to create a streamlined, automated system for strapping and protecting steel coils, resulting in improved productivity, efficiency, and safety.

Automatic steel coil weighing and label application machine

An automatic steel coil weighing and label application machine is a specialized piece of equipment used in industrial settings to accurately weigh steel coils and apply labels with important information such as weight, dimensions, and product information.

The machine typically consists of a conveyor system that moves the steel coils through the weighing and labeling process. The steel coil is placed on a weighing platform, which accurately measures its weight. Once the weight is determined, the machine applies a label with the corresponding weight and other relevant information to the steel coil.

Automatic steel coil weighing and label application machines can be customized to suit specific industry needs, and can handle a wide range of coil sizes and weights. They are commonly used in industries such as steel production, metal fabrication, and transportation, where accurate weighing and labeling of steel coils is crucial for inventory management and quality control.

It may include additional equipment such as conveyors, barcode scanners, and software for data management and analysis. These machines work together to create a streamlined, automated system for weighing and labeling steel coils, resulting in improved productivity, efficiency, and accuracy.

Automatic steel coil Stacking machine

An automatic steel coil stacking machine is a specialized piece of equipment used in industrial settings to stack steel coils in a predetermined configuration. The machine operates automatically and is designed to improve the efficiency and safety of the stacking process while reducing the need for manual labor.

The stacking process begins with the placement of steel coils onto the machine’s conveyor system. The machine then uses a variety of mechanisms, such as lift arms or forks, to pick up and move the steel coils into the desired stacking configuration. Once the coils are in place, the machine may also apply straps or other securing devices to hold the stack together.

Automatic steel coil stacking machines can be customized to suit specific industry needs, and can handle a wide range of coil sizes and weights. They are commonly used in industries such as steel production, metal fabrication, and transportation, where the efficient and safe stacking of steel coils is crucial for inventory management and quality control.

It also includes additional equipment such as conveyors, coil tilters, and packaging material dispensers. These machines work together to create a streamlined, automated system for stacking and protecting steel coils, resulting in improved productivity, efficiency, and safety.

What is the benefit of the automatic steel coil packaging line.

The automatic steel coil packaging line offers several benefits over manual packaging processes, including:

Improved Efficiency: The use of automated machinery in the packaging line allows for faster and more efficient processing of steel coils, resulting in higher production rates and reduced labor costs.

Consistency: Automated machinery is designed to perform tasks with a high degree of accuracy and consistency, ensuring that each coil is packaged in the same manner with the same level of protection.

Improved Safety: Automation reduces the need for manual labor, which can help to improve safety by reducing the risk of accidents and injuries associated with manual handling of heavy steel coils.

Customization: Automated packaging lines can be customized to meet specific industry needs, allowing for the packaging of steel coils of varying sizes, weights, and configurations.

Quality Control: Automated packaging lines can include inspection and monitoring systems that help to ensure that each coil is packaged to the required specifications, reducing the risk of quality issues and customer complaints.

The use of an automatic steel coil packaging line can help to improve efficiency, consistency, safety, and quality control in the packaging process, leading to improved productivity and profitability for businesses in the steel industry.