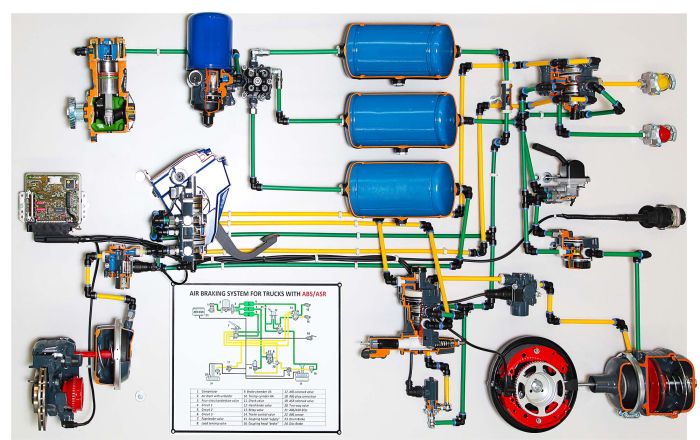

Air Brake Systems for Trucks and Trailers

When searching for a replacement for American truck parts, brake components rank high among those that must be handled carefully. Air brake systems are used on heavy vehicles and must be regularly serviced. It uses high-quality brake controllers, actuators, and friction materials.

An air brake system comprises numerous intricate parts and fittings. Making it essential for all components to be in optimal condition to ensure proper functionality. This article examines why air brakes are used on vehicles and the parts and fittings you should know.

The Advantages of Air Brakes

Here are five benefits of air brakes:

· Reliable Stopping Power:

Air brakes are known for their exceptional stopping power. Air brakes can provide consistent and reliable performance even under heavy loads and adverse conditions. It is by using compressed air to transmit force.

· Heat Dissipation:

Air brakes are designed to dissipate heat effectively. The braking system uses compressed air to compress brake pads or shoes against the braking surface, generating friction and heat. A continuous supply of compressed air helps prevent overheating. A common concern with other braking systems.

· Independent Operation:

Each braking unit in an air brake system operates independently. If there is a failure in one unit, the other brakes will continue to function. It ensures a certain level of safety and control. This redundancy and independence enhance overall braking reliability.

· Adjustable Braking Power:

Air brake systems allow for easy adjustment of braking power. The braking force can be altered per the vehicle’s load. Or the desired stopping intensity by varying the air pressure applied to the braking units. This adaptability makes air brakes suitable for various applications and assists in achieving optimal braking efficiency.

· Reduced Brake Fade:

Brake fade occurs when repeated heavy braking causes a significant drop in the braking system’s performance due to heat buildup. Air brakes are less prone to fade compared to hydraulic brakes. As air brakes have a larger capacity for heat dissipation, they can maintain their braking effectiveness for longer durations. Thus, it minimises the risk of brake fade.

Inspection Of The Air Brake System

You should hire a skilled diesel mechanic to handle the servicing and replacing worn or broken parts. However, it is essential to realise that regular brake system maintenance can reduce downtime. It can be done by preventing the unexpected failure of components that can lead to extended lengths of time in the repair shop. Regular maintenance for an air brake system involves:

- Valve failure in the primary and secondary circuits must be checked.

- Check for damage and leaks.

- Check the brake callipers and slack adjusters to make sure they are in good operating order.

- Check for weak or damaged springs.

- Verify that there are no breaks or damage to the brake lining or pad friction material.

- Check for signs of uneven wear.

Types Of Air Fittings For Air Brake Systems On Vehicles And Trailers

You should always try to get the highest possible quality when replacing Japanese truck parts. All replacement components must perform to or better than OEM standards. You may need to replace some of the following features:

- Shock absorbers

- Brass Fittings

- Fusion components

- Couplings

- Compression DOT Connectors

- Push-to-connect DOT adapters

Conclusion

Even if you do not undertake the repairs and maintenance yourself, you should have final control over the components used. Clarify to your truck’s mechanic that you are only interested in high-quality replacements.

Investing in high-quality European truck parts will increase the dependability of your air brake system and reduce the frequency of repairs, resulting in reduced downtime. Invest in high-quality aftermarket components for your truck to extend your driving time.