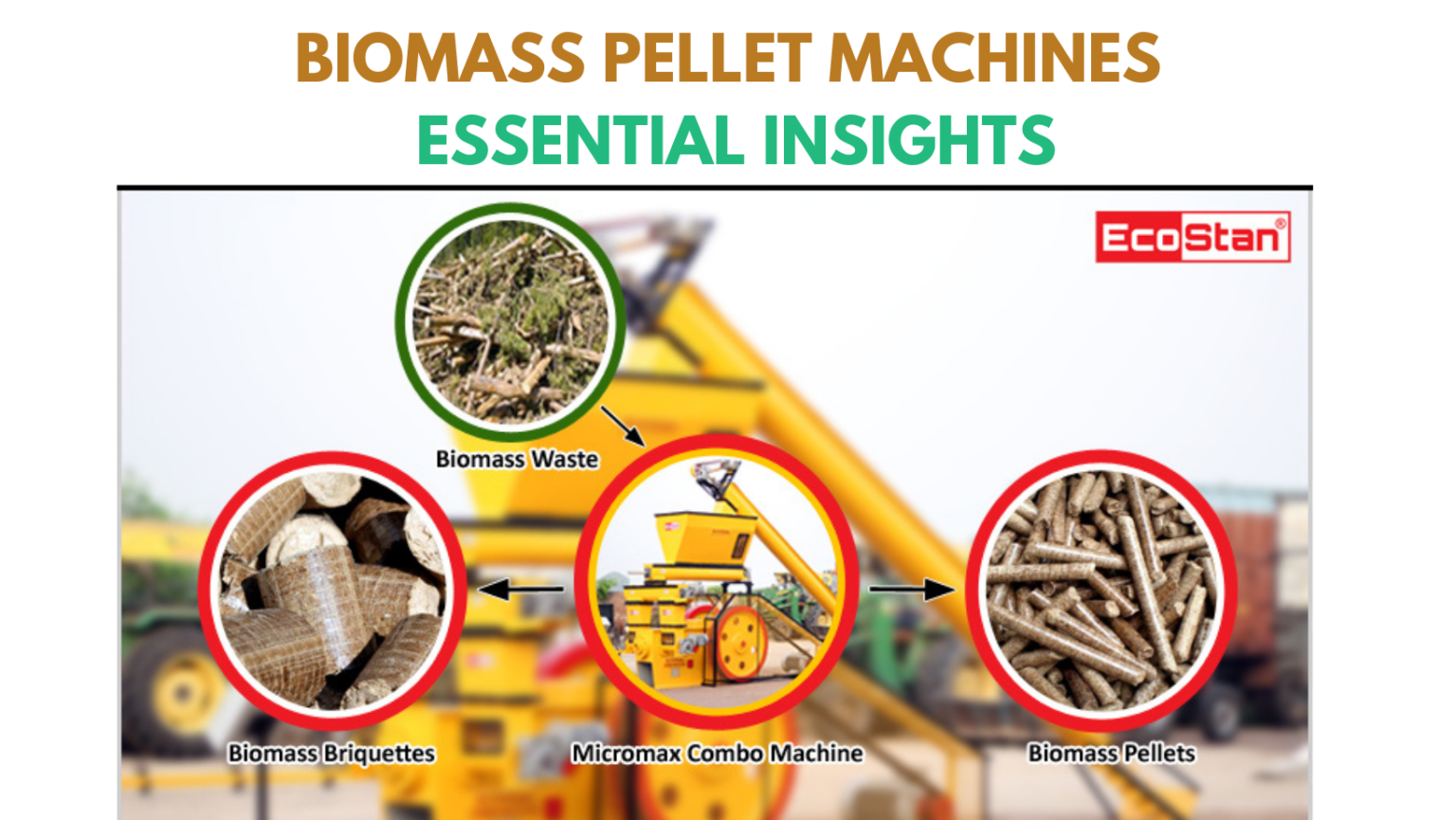

Biomass Pellet Machines:Essential Insights

We know that the world is facing severe climatic changing conditions. States, governments, and MNCs are trying their best at their levels to tackle the deteriorating situation. Different institutions are adopting renewable or green energy sources like solar, wind, biomass, etc. According to biomass pellet machine manufacturers, biomass energy is one of the best and easiest-available sources. Eco Stan Machineries, a well-known and credible Briquette cum Pellet machine firm, shares information on essential insights into biomass pellet machines and what you must know about them.

About Biomass Pellet Machine

We know that Biomass Pellet Machine is gaining popularity worldwide because of its eco-friendly working culture. You can imagine the credibility, not only industrial level but at the domestic level also, the demand for the Briquette cum Pellet machine is increasing. However, biomass pellet machine manufacturers have adopted the design and technology so that an unskilled individual can operate it easily. The person does not require special training or technical skills to work on the machine. If you want to purchase a new Biomass Pellet Machine or try hand for the first time, you should know some basics.

Types of Pellet Machines

Pellet machines divide into two sections according to their pellets-making process.

The Flat Die Pellet Machine

The flat die machine has a simple but compact structure. The owner can adjust its pressure according to different raw materials.

Ring Die Pellet Machine

The ring die machine is comparatively advanced in nature. It can manage with less power consumption and produces higher-quality output.

Raw Materials for Biomass Pellet Machine

First-time users or customers don’t know the raw materials for biomass pellet machines. A Biomass Pellet Machine requires common raw materials like wood, dust, rice straw, cotton stalk, corncob, wheat bran, sawdust, and other agricultural or forest wastes. House waste or cattle produce also can use for making pellets.

Power Sources of Biomass Pellet Machine

Biomass Pellet Machines are to design to meet the requirement of different types of clients. From small businesses to large industries, you can find many ranges. Even you can find it for the household. These machines can use conveniently 4 sources of energy. These are electricity, diesel, gasoline, and PTO.

Three Things You Should Know About How to Make Wood Pellets

Generally, new users find in confusion how to get the maximum from the pellet machine. Such users notice the following points before using or applying raw materials to the pellet machine.

The Moisture Content

We know that pelletization is a procedure of pressing and binding biomass powder or raw particles into pellets. The process works under high temperatures and pressure. So, enough water content requires protecting the material from charring during the pellet formation or pelletizing procedures.

Actually, different biomass waste products imbibe different moisture levels, but below 16% considers the best to shape pellets. If the moisture content is high, the pellet quality will be affected.

Particle Size Below 6 mm

A less than 6 mm sizes raw material is best suited to Biomass Pellet Machine for making good quality pellets. According to machine operating experts, the owner must ensure the raw material processes to a small size below 6 mm before feeding them into the machine. If your raw material is wood logs, you need a log splitter, wood chipper, and hammer mill to produce pellets.

The hammer mill is the best crushing machine for making pellets from wood chips. If you have reeds or straw, a hay cutter requires chopping the material. If you want to make pellets from sawdust or bamboo dust, you do not have crushing process anymore.

Tips for Biomass Material Mixes

The biomass pellet machine manufacturer can use soft and hardwoods to produce pellets. It could not wise to mix soft and hard woods because different materials require vivid additives and moisture content to make good-quality pellets. If the owner mixes both it would not be easy to control the process and produce good-quality products.

So, whenever you want a mixture of different waste materials, choose them with the similarities of their characters. As will be the similarities in characters of the raw materials mixture as would be the better pellets quality. The owner can follow a simple principle to produce high-quality outputs with a consistent raw material ratio, mixed in a proportional mill and suitable additives.

Conclusion

Biomass pellets are one of the best green energy sources. Biomass Pellet Machine is the best equipped with tools and techniques to produce high-quality biomass pellets using raw materials like wood chips, agro waste, house waste, sawdust, etc.