Acquiring Best CNC Machining and Its Parts: From Services to Parts Material Quality

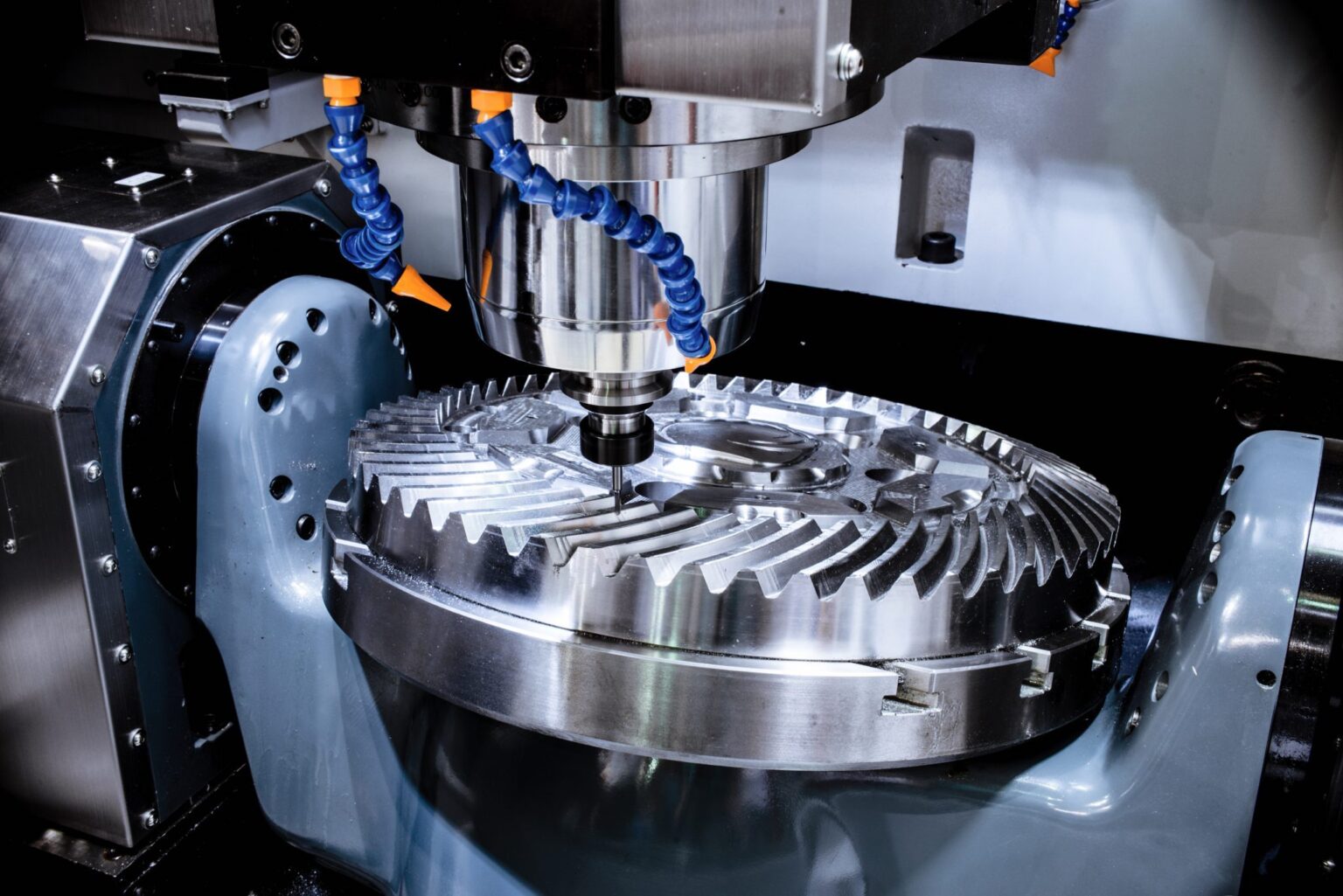

CNC machining stands for computer numerical control. By removing the superfluous material from blocks or cylinders of materials that are plastics or metals, CNC machining is a potent technique that produces pieces from the materials. To regulate the accuracy and quantity of material removed, it employs cutting tools with sharp edges that come in a variety of forms and sizes. It is a very accurate and precise method that is employed for the creation of prototypes and finished goods. However, the issue that emerges here is how to pick the best CNC machining firm out of everyone. Here are the guidelines for that:

Roadmap for choosing best CNC machining

- Engineering and apparatus: Examining the company’s technology and equipment is a crucial factor to take into account when picking the best CNC machining company. You can choose a firm that meets your production needs by researching the technology they employ or the equipment service they offer for product machining.

- Discover Your Slot: While searching for the best CNC machining firm, your product needs or project requirements should be one of the main considerations.

- Customer dealership: It’s crucial to research the customer service and responsiveness your preferred CNC machining company provides, just like you would with any other professional service or company you choose to invest in. You can gain a better understanding of how the business interacts with its clients by reading reviews and testimonials from other clients as well as business owners.

- Sector Acceptance: Some professions call for licensing. They serve as evidence that a reliable and knowledgeable external party has confirmed the manufacturer’s possession of the tools and staff required to maintain the quality management system, as well as its installation and proper operation.

However, Prototool, which is regarded as one of the best CNC machining companies for a reason, offers all these top attributes.

Examining the specifics of CNC machining parts:

The build quality of CNC machining parts is more important than anything else. Simple metal fasteners and complex engine parts for aeroplanes are only two examples of the many industries that use CNC machining parts. Prototool, the best CNC machining company, provides this assurance to its consumers. The CNC machining part is used to create products that we use in everyday life. We rely heavily on them. They are utilised as spare parts or tooling surfaces and range in complexity from simple to complicated designs. When CNC machining parts are used in projects, the benefit of CNC-crafted parts with established qualities as a production technology is also introduced. In particular, machining offers dependability and predictability and has been the norm in the industry for decades. In order to increase their suitability for a variety of applications, CNC machining parts are therefore ready to align with industry-specific standards and certifications. In this article, we will discuss the specifications of materials used in making CNC machining parts by prototool and how they distinguish them from others.

Quality guideline about materials

- Resilience: Since CNC machining parts are constructed from solid blocks of material, their innate strength is a considerable advantage. This solid underpinning gives these components exceptional longevity and robustness.

- Transformation: Additionally, the fact that CNC machining parts can take on a variety of shapes and thicknesses illustrates how versatile they are. This adaptability enables complex designs and numerous proportions tailored to particular requirements.

- Enticement: The precision of parts produced after machining is another impressive aspect of Prototool CNC machining parts. Their production strategy permits the incorporation of intricate and minute details, which enhances the end product’s functionality and appeal.

Conclusion:

While selecting the best CNC machining companies, it’s crucial to consider whether they offer excellent customer service, dependability, cutting-edge technology, and high-quality materials for creating CNC machining parts. Embrace the world of CNC machining, and let Prototool be an escort.