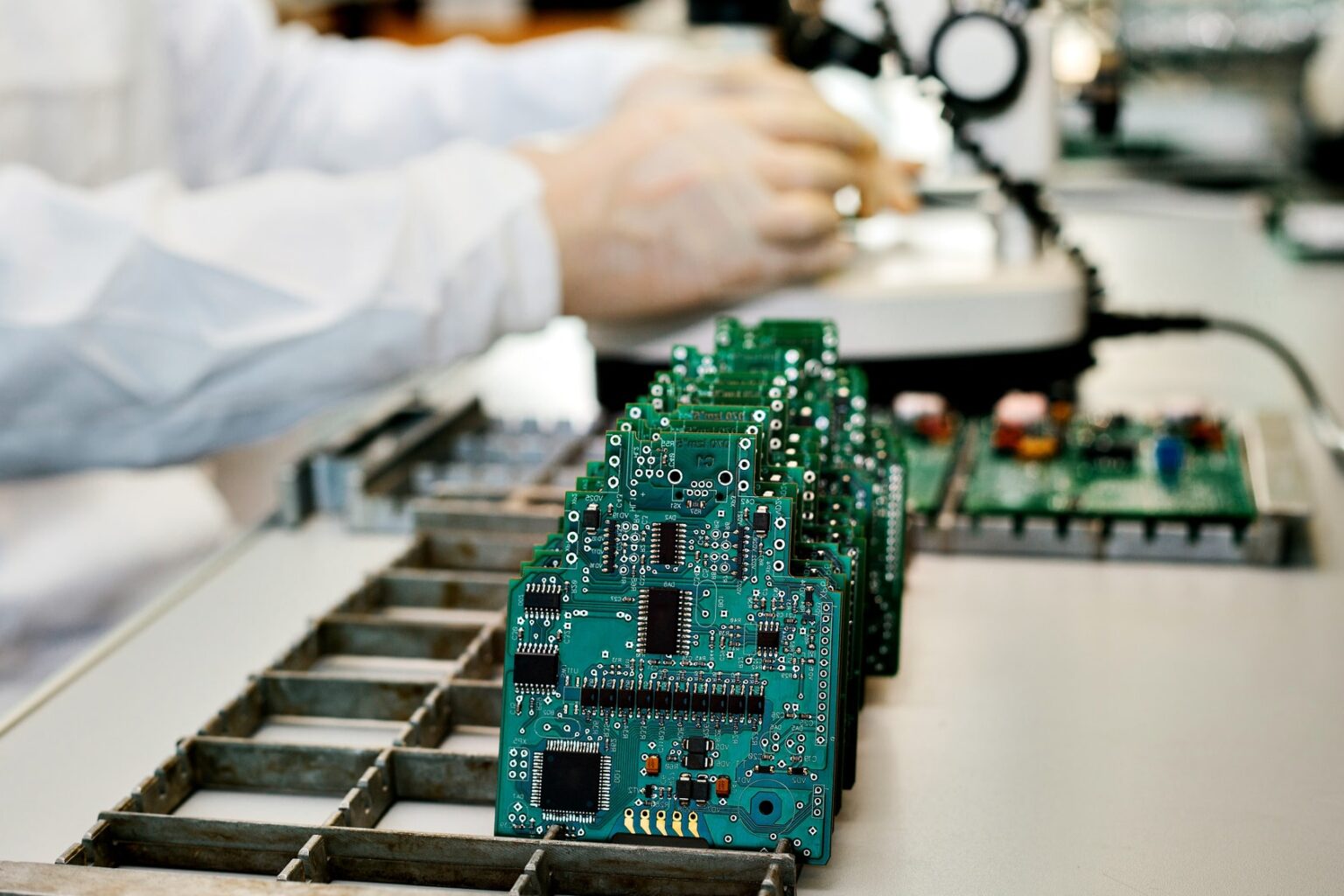

DFM: is your PCB design ready for manufacturing

Printed Circuit Board (PCB) design quality and efficiency are crucial in the competitive electronics industry of today. Ensuring your PCB design is functional and optimized for the manufacturing process is the responsibility of Design for Manufacturing (DFM). An in-depth discussion of DFM and its relevance to PCB design is provided here.

What Does PCB Design Do in Production?

The importance of printed circuit board (PCB) design to the manufacturing process must be grasped before diving into the mechanics of DFM. A well-planned PCB design does more than just guarantee that your electronic gadget will work as advertised. A well-thought-out design cuts production time and costs while also raising output quality.

A Brief Overview of DFM’s Core Principles

Location of Parts

The foundation of a well-designed printed circuit board (PCB) is careful component placement. Proper placement of components is essential to the board’s functionality and facilitates quick and straightforward assembly in production.

Links and Paths

A PCB’s traces and routing must be carefully planned to prevent signal interference and guarantee a steady current. Signal crosstalk and EMI are reduced with a well-routed PCB.

Stacking of Layers

A PCB’s layer count is an important design parameter. The board’s size, cost, and manufacturing complexity can all be impacted by the number of layers used in its construction. DFM relies heavily on this factor being optimized.

Controlling Temperature

Overheating might damage the system, therefore, it’s essential to keep things cool as much as possible. Heat sinks and vias can effectively remove thermal energy when appropriately designed.

PCB Layout Benefits from DFM

Several advantages can be gained by adopting DFM practices. It decreases manufacturing mistakes, speeds up production, and saves money. It also boosts the end product’s quality and reliability.

The DFM Software and Toolset

Many applications and hardware gadgets can help you carry out DFM efficiently. These aids let designers spot and fix manufacturing flaws before they go into production.

Cooperation with Industrial Producers

You can only succeed in manufacturing with tight cooperation with your partners. They can help you improve your design’s DFM features by giving you advice and suggestions.

Example of Effective DFM Deployment

Looking at real-world case studies of effective DFM implementation can teach PCB designers a lot. These illustrations illustrate the practical advantages of DFM.

Saving Money and Increasing Productivity

As a result of improved efficiency and fewer mistakes in production, DFM can result in substantial savings. In addition, it improves productivity, which speeds up manufacturing and distribution.

Quality Control and Assurance

During production, quality control plays a crucial role. DFM guarantees that your PCB design is up to par. The DFM process includes exhaustive checking and testing.

The Way Forward for DFM

DFM is developing alongside technological advancements. Automation, artificial intelligence-assisted design, and improved DFM tools are all on the horizon, which bodes well for the future of PCB design and production.

Free DFM analysis

Some PCB (Printed Circuit Board) manufacturers provide a helpful DFM (Design for Manufacturing) study at no cost to determine whether or not your PCB design can be manufactured. free DFM analysis Skilled engineers will examine your design and suggest how to fix any manufacturing problems. Thanks to this review of your design’s feasibility, you can save time and money on production. Manufacturers provide this service for free to better work with their customers, speed up the design-to-production process, and ultimately provide better PCBs. It’s a terrific way to save time and money in the long run by allowing designers to get expert input and make improvements before manufacturing begins.

Online PCB quotation

If you or your company wants a price quote for printed circuit board (PCB) manufacture, an online PCB quotation is a quick and easy option. Using an online quotation system, customers can quickly acquire precise sources from PCB manufacturers by supplying design specifications, quantity requirements, and other essential parameters. This method speeds the process of purchasing PCB fabrication and assembly services by eliminating the need for extensive negotiations and back-and-forth communication between buyers and sellers. Online PCB quotations are famous for people looking for high-quality online PCB quotations for their electronic projects because they save time, streamline the ordering procedure, and provide cost transparency.

Conclusion

DFM is essential to printed circuit board (PCB) design. Adopting DFM principles guarantees a well-functioning PCB design and enhances its suitability for manufacturing. The correct DFM strategy can help you save money, improve your product’s quality, and keep up with the rapidly developing electronics market.