Energy Efficiency and Centrifugal Fans: Tips for Sustainable Air Handling

Centrifugal fans play a crucial role in various industrial, commercial, and residential applications, ranging from HVAC systems to industrial ventilation. Nevertheless, given the growing emphasis on sustainability and energy efficiency, it’s crucial to investigate methods for enhancing the performance of centrifugal fans to achieve sustainable air handling. In this blog post, we’ll delve into the key considerations and tips for enhancing the energy efficiency of centrifugal fans.

Understanding Centrifugal Fans

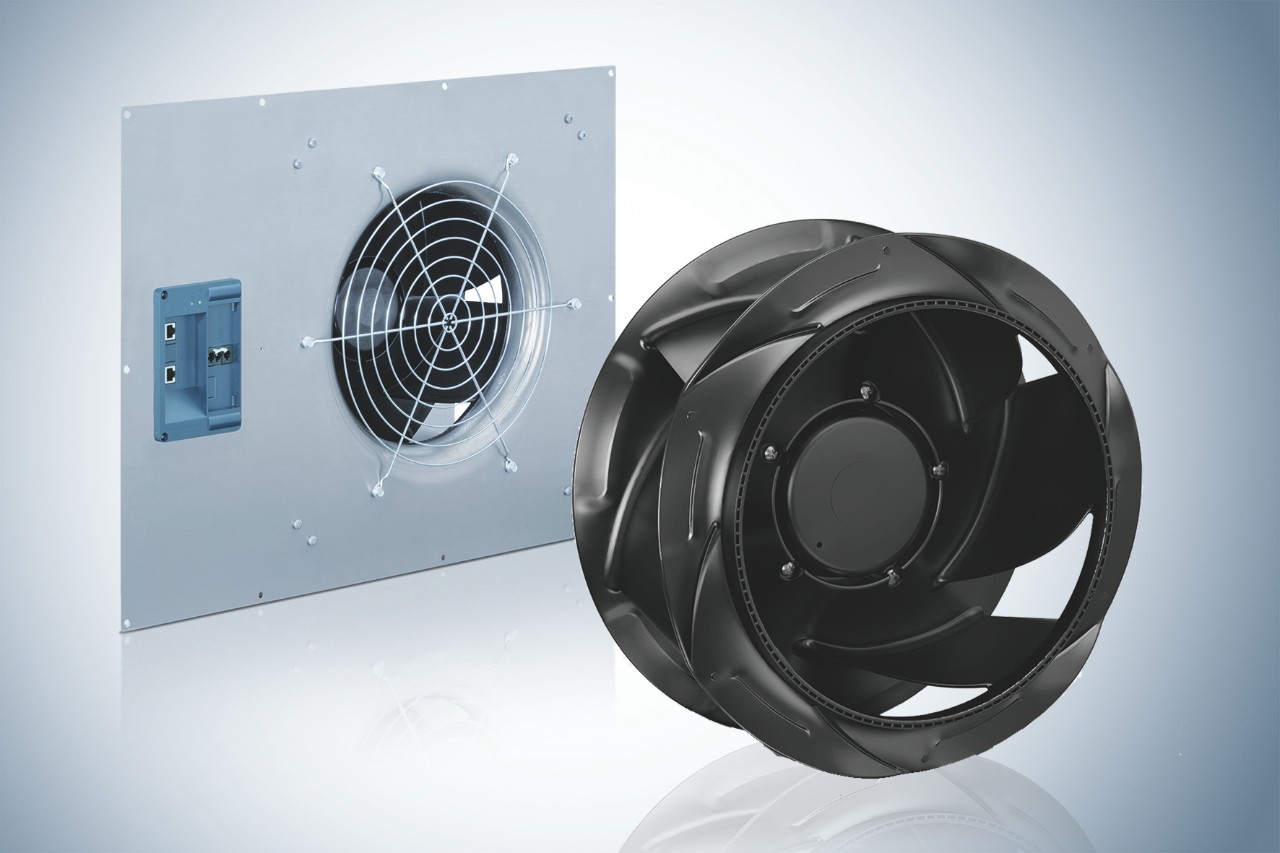

Before we dive into energy efficiency tips, let’s briefly understand how centrifugal fans work. In contrast to axial fans, which propel air in a linear direction, centrifugal fans operate by drawing air into the fan’s center and subsequently expelling it radially outward. This action creates a steady flow of air, making centrifugal fans ideal for applications that require higher pressure and flow rates.

Energy Efficiency Considerations

Select the Right Fan Type: The choice of the right Centrifugal fan type is crucial. Different types, such as forward-curved, backward-curved, or radial fans, have varying performance characteristics. Ensure that the fan type matches the specific requirements of your application to minimize energy waste.

Size Matters: Proper sizing of the centrifugal fan is essential for energy efficiency. An oversized fan can lead to excessive energy consumption, while an undersized fan may not meet your airflow needs. Seek advice from an expert to ascertain the appropriate fan size for your application.

Variable Speed Drives (VSDs): Consider using Variable Speed Drives to regulate fan speed. VSDs allow you to adjust fan speed based on actual demand, reducing energy consumption during periods of lower airflow requirements.

Efficient Motor Selection: Choose high-efficiency motors for your centrifugal fans. Energy-saving motors use less electricity while providing the required power for the fan’s operation.

Regular Maintenance: Establish a proactive maintenance timetable to ensure your centrifugal fan remains in optimal condition. Dirty blades, worn belts, or misaligned components can reduce efficiency. Routine cleaning and maintenance can avert these problems.

Balancing and Alignment: Make sure the fan blades are properly balanced and aligned. Imbalances and misalignments can cause vibration and energy loss, decreasing overall efficiency.

Ductwork Design: Meticulously engineered duct systems can have a substantial effect on energy efficiency. Properly sized and insulated ducts minimize air leakage and pressure losses, improving overall system efficiency.

Automation and Controls: Implement advanced control systems that can optimize fan operation based on real-time conditions and demand. Smart controls can help maintain consistent airflow while reducing energy consumption.

Consider Airflow Recirculation: In some cases, recirculating a portion of the exhaust air back into the system can improve efficiency by reducing the load on the fan.

Energy Audits: Perform routine energy audits to pinpoint areas where enhancements in energy efficiency can be implemented. This can help you fine-tune your centrifugal fan system for sustainability.

Conclusion

Centrifugal fans are indispensable for many applications, and optimizing their energy efficiency is a vital step toward achieving sustainable air handling. By selecting the right fan type, sizing the fan correctly, using variable speed drives, maintaining equipment, and employing advanced controls, you can reduce energy consumption, lower operating costs, and minimize your environmental footprint. Sustainable air handling with centrifugal fans is not only good for the planet but also good for your bottom line.

Integrating these suggestions for energy efficiency into your centrifugal fan system will not only improve performance but also support a more environmentally friendly and sustainable future. Keep in mind that each measure you adopt for energy efficiency brings you closer to minimizing your carbon footprint and preserving valuable resources.

FAQs: Energy Efficiency and Centrifugal Fans

Q1: What is a centrifugal fan, and how does it differ from axial fans?

A1: Centrifugal fans operate by pulling air into the center and expelling it radially outward, creating a steady airflow. Unlike axial fans that move air in a straight line, centrifugal fans are ideal for applications requiring higher pressure and flow rates.

Q2: Why is energy efficiency important in centrifugal fan systems?

A2: Energy efficiency is crucial for reducing operating costs, minimizing environmental impact, and promoting sustainable air handling. Optimizing centrifugal fan performance helps conserve energy resources and lowers carbon footprint.

Q3: How do I choose the right type of centrifugal fan for my application?

A3: Different types, such as forward-curved, backward-curved, or radial fans, have varying performance characteristics. Select a fan type that matches your application’s specific requirements to minimize energy waste.

Q4: What role does proper sizing play in energy efficiency?

A4: Proper sizing is essential to prevent excessive energy consumption (in the case of an oversized fan) or failure to meet airflow needs (with an undersized fan). Consult with a professional to determine the correct fan size for your application.

Q5: How do Variable Speed Drives (VSDs) contribute to energy efficiency?

A5: VSDs allow you to regulate fan speed based on actual demand, reducing energy consumption during periods of lower airflow requirements. They provide flexibility and control in optimizing energy usage.