Everything You Need to Know About Jaw Crusher

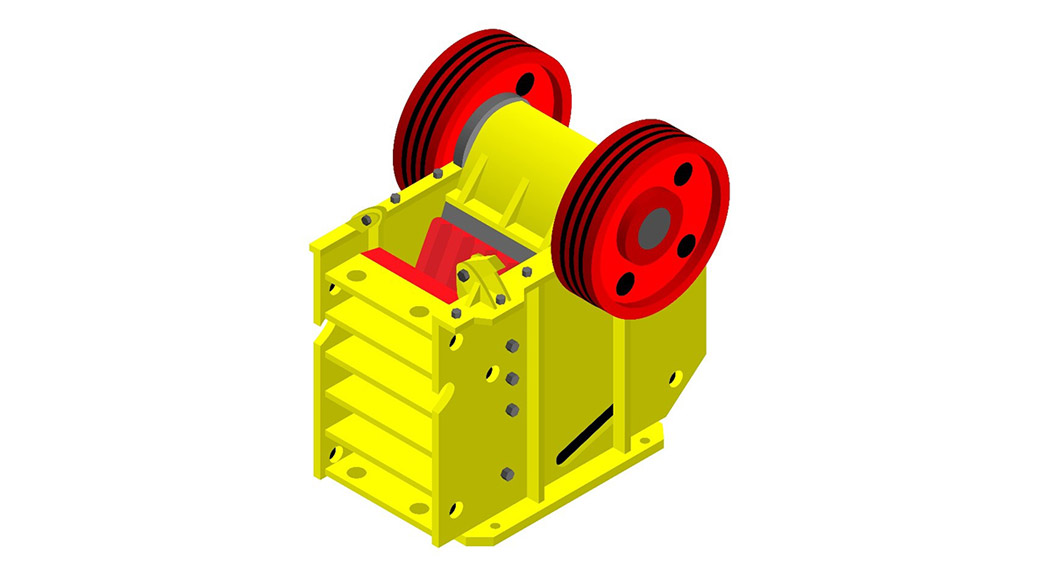

Crushers play vital roles in mining and construction by breaking down huge rocks into smaller pieces. There are various crushers, but the jaw crusher is the most popular because of its efficiency. Let us learn more about how a jaw crusher works, its components, and the whole process of crushing.

What are the Basic Principles of a Jaw Crusher?

A jaw crusher is a crushing machine that uses compression; it contains a moving jaw and a fixed jaw. The fixed jaw is set on the immovable surface, allowing the moving jaw to exert force against the fixed jaw breaking down the material between them. Simply put, the breaking down action is achieved through various jaw plates, which break down particles by applying pressure.

What are the components of a Jaw Crusher?

The first component is the fixed jaw, also known as the immovable or stationary jaw, which is a vital part of the crusher frame. It is made of solid metal to provide strength to withstand the strong forces that unveil when the breakdown occurs.

The movable jaw is another component of a jaw crusher. The jaw is also called the swing jaw. Its primary purpose is reciprocated forth and back against the stationary jaw, which in turn allows the crushing of all the materials. The movable jaw is positioned and attached to the eccentric shaft that allows the jaw to move horizontally and vertically.

The eccentric shaft is a very crucial component of the jaw crusher. It is because the eccentric shaft serves as the driving force behind the movement of the jaw crusher. The next question in your mind is how the eccentric shaft operates. The eccentric shaft rotates, causing the stationary jaw to move in an oval-shaped motion which results in the crushing action.

Another component of the jaw crusher is the toggle plate. The toggle plate offers safety by acting as a safety mechanism. The compressive forces generated during crushing must be regulated; the toggle plate transmits the troops. In some rare cases, when there is an overload, the toggle plate breaks to protect the jaw crusher from damage.

The flywheel is a component of the jaw crusher, and as the name suggests, it is a heavy-duty wheel. The flywheel is attached to the eccentric shaft; its purpose is to provide a consistent motion to the crusher and storing of energy, enabling a smooth crushing process.

What are the types of Jaw Crushers?

Various types of jaw crushers are designed by crusher manufacturers to perform specific purposes. Here is a list of the popular jaw crushers: Single-toggle jaw crusher, Double-toggle jaw crusher, Blake jaw crusher, Dodge jaw crusher, Universal jaw crusher, and overhead eccentric jaw crusher.

Single-toggle jaw crusher: Contains only one toggle plate that moves horizontally and vertically, enabling crushing action. In this jaw crusher type, the stationary is positioned at the top. It works by pushing materials toward the fixed jaw.

Double-toggle jaw crusher: As the name suggests, this type contains two swinging jaws. The jaws have support at the bottom and top, allowing outward and inward movement as the eccentric shaft rotates. It is designed to offer a larger breaking-down capacity than a single-toggle crusher.

Blake jaw crusher: This type contrasts the double-toggle jaw crusher. It contains a pivoted swing and a fixed jaw plate that moves in an arc motion. The Blake jaw crusher is mainly used for crushing coarse and medium materials.

The Crushing Process

The crushing starts at the feed hopper, where the materials are loaded. From there, the feed hopper directs the materials to the jaw crusher. Once the materials are inside the jaw crusher, they come across the crushing chamber. The crushing chamber is where the movable and fixed jaws come together. Here the crushing of materials begins reducing the materials into smaller particles. The movable jaw continues to move in an elliptical motion enabling the progressive crushing of materials into smaller particles. When the material is crushed into the desired size, it gets out through the discharge outlet, which is located at the bottom of the crusher.

What are the benefits of Jaw Crusher?

Jaw crushers are versatile machines, making them suitable for breaking down and crushing various materials such as granite, ores, and basalt.

The jaw crusher has very high efficiency, mainly due to the design since it provides a large opening and steep chamber angle, ensuring optimal throughput.

The jaw crusher has high durability and reliability. It is built to withstand heavy-duty operations and also harsh environments. It also has low maintenance costs and can last for an extended period.

Jaw crushers are mainly used as primary crushers in quarrying operations, where they crush large rocks into smaller ones for further processing.

Conclusion

A jaw crusher is an efficient and robust machine created to help break or crush large rocks into smaller particles. Its design is straightforward yet powerful. Its high efficiency and versatility make it the most commonly used machine in construction industries and mining.