How to Properly Dispose of Old Televisions

Introduction

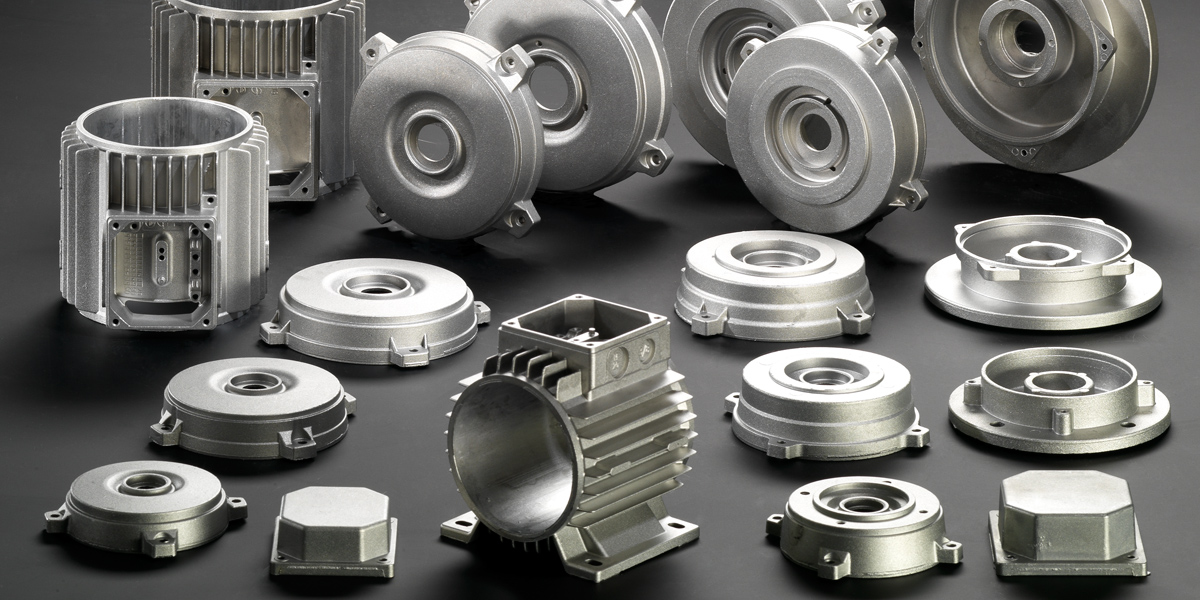

In today’s era of rapid technological advancement, the television, as the core device of home entertainment, has undergone a massive transformation from bulky CRTs to modern slim LED screens. With the constant emergence of new technologies, old televisions are gradually being phased out, becoming electronic waste that needs to be dealt with in households. However, many people lack sufficient knowledge and understanding of how to properly dispose of these old televisions. Old TVs not only contain harmful substances commonly found in electronic waste, such as lead and cadmium, but also a large amount of recyclable materials, such as plastics, glass, and metals. Among these components, metal parts are often manufactured through a “die casting” process, which makes them especially important in recycling and disposal.

Proper disposal of old televisions is not only an environmental necessity but also a crucial aspect of resource recycling. With the increasing awareness of environmental protection and the advancement of recycling technology, understanding and practicing the correct methods of disposing of old televisions becomes particularly important. This article aims to provide readers with a comprehensive guide on how to properly handle old televisions, with a special focus on the role and opportunities of the die casting industry, and explores how to efficiently utilize the valuable resources in these discarded electronic products while ensuring environmental safety.

Environmental Impact of Old Televisions

With the rapid development of television technology, old TVs have gradually become waste in homes and offices. These obsolete televisions not only occupy a lot of space but more importantly, they pose potential threats to the environment. Old TVs contain various toxic substances, such as lead, mercury, and certain stabilizers. If not properly handled, these substances can seep into the soil and water sources, causing long-term effects on human health and the ecosystem.

In addition to the issue of harmful substances, old televisions also contain a large amount of recyclable materials, such as plastics, glass, and various metals. The metal parts, in particular, are often manufactured through efficient and economical “die casting” processes. This manufacturing process not only ensures the precision and durability of components but also makes these metal parts more significant in recycling. Proper recycling of these materials can reduce environmental pollution and save natural resources and energy.

However, when dealing with old televisions, many people are unaware of these potential environmental risks and recycling values, leading to a large number of old TVs being simply discarded or improperly handled. This not only wastes valuable resources but also exacerbates environmental pollution. Therefore, raising public awareness of the importance of recycling old televisions and promoting correct recycling methods have become important tasks we face.

The Role of Die Casting in Old Television Recycling

Die casting technology plays a crucial role in the manufacturing process of televisions. This technology is mainly used to produce metal components of TVs, such as stands, internal frames, and connectors. These components provide structural support for the television and ensure its durability and stability. Due to the precision with which complex metal components can be manufactured, die casting has become an indispensable part of television manufacturing.

In the recycling process of old televisions, die-cast components are equally important. First, these metal parts are usually made of aluminum, zinc, or other recyclable metals, making them highly valuable in the recycling process. With proper treatment and reuse, these metal parts can reduce the demand for new resources while lowering the environmental impact of manufacturing new televisions.

Second, due to the durability and stability of die-cast components, they are relatively easy to identify and separate during the disassembly process of televisions. This is crucial for efficient and environmentally friendly recycling. Effectively separating and recycling these metal parts not only reduces the amount of waste in landfills but also prevents the release of toxic substances, thus protecting the environment.

However, despite the key role die-cast components play in television recycling, there are still challenges in practice. For instance, precise sorting and separation techniques are needed to process these parts to ensure effective recycling. In addition, the public and recycling companies still lack sufficient understanding of the value and methods of recycling these components, which is an issue that needs to be addressed in promoting old television recycling.

Recycling Process and Methods

The recycling of old televisions is a complex but crucial process, involving accurate disassembly, classification, and processing of various materials. Understanding and following the correct recycling process not only protects the environment but also maximizes resource recovery.

Television Disassembly

The recycling of old televisions begins with careful disassembly. This step requires professional knowledge to ensure hazardous substances (such as lead and mercury) are safely handled while preserving recyclable parts. During disassembly, professionals divide the television into several main parts, including the screen, circuit boards, plastic casing, and metal components.

Classification and Separation

The disassembled parts need to be classified and separated. For metal components, especially those manufactured using die casting technology, they are usually made from easily recyclable materials like aluminum or zinc. These metal components should be collected separately for subsequent recycling processes.

Recycling of Metal Components

The recycling of die-cast metal components involves melting and purifying these metals, and then recasting them into new products. This process not only saves resources but also reduces the energy and raw materials needed to manufacture new components.

Processing Other Materials

In addition to metal components, other materials in old televisions, such as plastics and glass, also need to be recycled. These materials can be reprocessed into new products, reducing the demand for new resources.

To improve recycling efficiency and environmental protection, not only technical and equipment support is needed, but also an increase in public awareness of the value of recycling old televisions. Moreover, manufacturers and government agencies can promote effective recycling of old televisions by establishing related policies and recycling standards.

Case Study: Successful Examples of Television Recycling

Green Recycling Program

In Europe, there is a widely recognized green recycling program specifically targeting electronic waste, including old TVs. This program establishes a series of collection and processing centers in collaboration with local governments and environmental organizations. At these centers, old TVs are precisely dismantled, with special attention given to their die-cast metal components to ensure effective recycling. This program not only increases the recycling rate of old TVs but also reduces environmental pollution, serving as a model for other countries and regions.

Innovative Recycling Model of a Die-Casting Company

In Asia, a large die-casting company has developed an innovative recycling model for old TVs. This company has established a recycling network that encourages consumers to bring their old TVs to designated collection points. The recycled TVs are first professionally dismantled, and then the die-cast metal parts are processed separately. This model not only improves the efficiency of metal recycling but also provides an additional source of raw materials for the die-casting industry, reducing the reliance on new resources.

These cases demonstrate that with the right strategies and technologies, the recycling of old TVs is not only possible but also significantly impacts environmental protection and resource conservation. These successful experiences offer valuable references for global old TV recycling efforts.

Opportunities and Challenges in the Die-Casting Industry for Old TV Recycling

The die-casting industry faces both challenges and unique opportunities in the recycling of old TVs.

Opportunities

New Source of Raw Materials: As TV recycling efforts progress, the die-casting industry can obtain a large amount of recycled metal, which can be used to produce new components. This provides the industry with an economically and environmentally friendly source of raw materials.

Innovation in Technology and Business Expansion: TV recycling opens up a new business area for die-casting companies. They can expand their business scope and market share through technological innovations, such as improving metal recycling and processing techniques.

Pioneering Role in Sustainable Development: Actively participating in TV recycling not only enhances a company’s environmental image but also allows it to take a leading position in the trend of sustainable development.深圳 邪 骨

Challenges

Technological and Financial Investments: Effective TV recycling and metal processing require advanced technology and equipment, which may necessitate significant initial and ongoing R&D investments.

Market and Policy Uncertainty: The market demand and policy environment for electronic waste recycling can change over time, bringing uncertainty to long-term planning for die-casting companies.

Lack of Public Awareness and Partnerships: Promoting TV recycling requires widespread public participation and awareness, as well as collaboration with governments, environmental organizations, and other businesses. This demands efforts from the die-casting industry in terms of outreach and cooperation.

In summary, the die-casting industry has tremendous potential for development in the recycling of old TVs but also faces multiple challenges. By actively addressing these challenges and fully leveraging these opportunities, the die-casting industry can play a significant role in environmental protection and resource reuse.