Termodizayn Cooling Systems

Termodizayn Cooling Systems contributes to the cooling chain with its hygienic cold storages suitable for the storage of the foods it produces and with container type portable cooling systems.

Termodizayn Cooling Systems provides services with Solar Powered cold storages of various capacities, mobile shops, Freezing Rooms, and cooling units. The company, which produces cooling machines, which is a technological product, aims to invest in innovations and development.

TERMODİZAYN, which started its activities as a family company in 1987, took its first step towards institutionalization in 2000. It was completely domestically funded and established by experts in the field. Since its establishment, the company has continued to develop its “cooling systems manufacturing, assembly and service” activities until today. Termodizayn officials state that they will undertake projects that will make Turkey’s name known to the whole world with new technologies and R&D studies.

Knowing that the best advertisement is customer references, and believing that customer satisfaction passes through quality, Termodizayn has been continuing its production for years without sacrificing customer satisfaction.

Termodizayn expresses its Cooling Systems Units as follows:

Industrial Type Cold Storages

There are 4 main elements in Cold Storage that the whole world agrees on.

1- Isolation

2- Sufficient Volume for Need,

3- Warehouse suitable for the product to be stored

4- Proper Cooling System

The most indispensable element is the right isolation and the right cooling. For the last 10 years, a consensus has been reached on the opinions that the most suitable material is polyurethane-filled panels. In our country, where the energy cost is very high, if the warehouse is not properly insulated, a healthy efficiency cannot be achieved and it also increases the operating cost. At this point, Termodizayn stands out by providing the most accurate insulation and cooling system.

Cooling Devices

Termodizayn cooling devices have Split type cooling units and wired remote control panel. In Termodizayn Cooling units, maximum attention is paid to the compatibility of the compressor, condenser and evaporator with each other. Efficiency quality is high in Termodizayn units. It complies with European Union norms and is produced with CE label.

Ultra Low Temperature Cascade System Units

-60 / -65 C Ultra Deep Cooling Units are manufactured by applying cascade cooling system. Ultra Deep Cooling Units are the latest technology specially designed by Termodizayn.

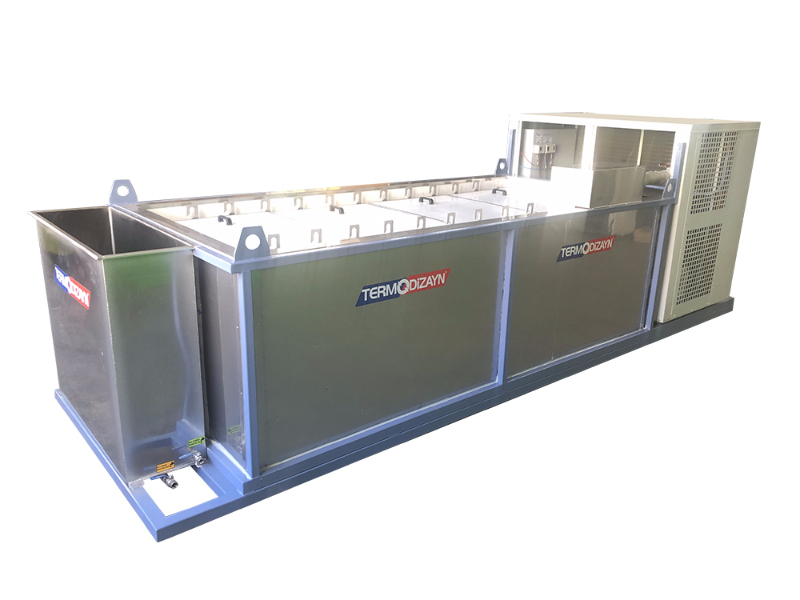

Container Type Mobile Blast Freezers

Termodizayn containerized blast freezers give you many advantages because it is portable, you can place or move them where ever you want or you can even rent.

Assembly and dismantling of the isolation panels of stationary blast freezing rooms can be quite expensive. The panels will possibly be damaged with multiple disassemblies. That is why many facilities and especially fishing companies prefer portable containerized blast freezers.

Termodizayn mobile blast freezers are in accordance with the international standards for truck transportation. Production of special sizes are also possible for overseas transportation.

Entrance door width may vary between 90cm and 130cm. Surface material is made of PVC coated galvanised metal sheets and optionally stainless steel. It can operate smoothly even in the desert type tropical conditions. Double stage compressors are picked among world wide known brands.

Water Chiller For Bakery

Termodizayn industrial bakery chillers have been designed for high-performing and intensive production. In order to offer a customized solution to any request, the tank capacities vary from 80 to 150 liters and their size has to be chosen according to the amount of water needed for the single maximum delivery for one mixer (or more mixers simultaneously, depending on the production system).

Thanks to the plate heat exchanger, the water in the tank is cooled very quickly in the interval between one delivery and the following. The entire series is equipped with an electronic controller which supervises all the functions.

-Low energy cost, efficiency

-Hygiene standard, all parts stainless steel

-Smart design

-User friendly, easy to use

-Durability

-High performance

Fresh Water Cooling Units

Termodizayn fresh water cooling devices are developed for your existing ice machines, aiming at increasing your ice quality by pre-cooling the water used in ice production.

Refrigerated Sea Water (RSW) Chiller Unit

Termodizayn Refrigerated Sea Water (RSW) systems are used onboard fishing vessels to preserve large catches. Storing the catch in an RSW system is an effective and cost-saving method of preserving the catch until offloading ashore or further processing onboard. In a minimum amount of time the catch is cooled down close to the freezing point of seawater, assuring its freshness and quality during transport.

In an RSW system, seawater is recirculated by pumps through the tanks and the chilling system. Before entering the tanks, the seawater is chilled by the refrigeration equipment. The seawater is distributed evenly over the complete bottom cross-section of the tanks through a set of perforated plates or similar distribution devices. The chilled seawater passes upwards through the tank and layers of fish, thus keeping the fish semi-floating and simultaneously cooling it. The water returns through suction screens in the top of the thanks to the chilling unit of the system and, subsequently, the circulation process is repeated.

Concrete Cooling Water Chillers

All around the world, temperature controlled concrete is used to build large sized sets and to fill in the large scaled bases of high buildings. The heat exchanged with water during the process, increases the temperature of the concrete to 25C, causing the volume to expand. However, after the operations, the temperature of the concrete falls and the volume shrinks. The above-mentioned process generally leads to cracks in the sets, so the initial filling temperature of the concrete should be low enough to ensure that the maximum temperature reached during the operations does not exceed the value set by the design units. Using + 1C / + 2C cold water together with the flake ice is the most effective precooling method. Every 10kg of flake ice reduces the temperature of concrete down to 12C to 14C.

Termodizayn fulfills the needs of some of the world’s largest ice facilities for concrete cooling projects.

Blast Chillers

- Rapid cooling capacity (product core temperature): from +5 ° C to +63 ° C 2 hours (max.100kg)

- Quick freezing capacity (product core temperature) + 63 ° C to -18 ° C 4.5 hours (max.100kg)

- Complete internal and external surfaces of stainless steel 304 cr.n

- High air speed evaporator system

- Manual defrost system

- Double digital control panel (cold & frozen)

- 100mm thick polyurethane insulation

- Rising hinged door system

- Lockable and can be opened from the inside “security door”

- Ramp for easy loading

- Split cooling unit that can operate in hot climates

Refrigeration Equipments

All refrigeration equipments used in industrial cooling systems and ice machines can be supplied as spare parts from Termodizayn

Cold Room Panels (Sandwich Panels)

With the advances in technology, the importance of keeping foodstuff in appropriate conditions has been understood. The two most important issues in the keeping of food substances are the cooling equipment and establishing a cold storage. The two important issues while establishing a cold storage are materials with isolation power, and hygienic surface materials. The most ideal material with the necessary high isolation power is polyurethane. PVC or polyeshtere coated galvanized sheet metals, used as surface material, form the desired hygienic and easy to clean surfaces.

Cold room panels are acquired in fabrication environment by injecting polyurethane under high pressure. During the production of the panels, cold room panels become prefabricated and easy to mount, by placing locks inside the panel body. In all the industrial facilities using modern technology nowadays, cold storages are established by using prefabricate panels.

The polyurethane filled prefabricate sandwich panels used in thermodesign cold storage, are the most ideal material in heat insulation, providing perfect results due to technical features, durability and easy erection. Wall and roof panels are being produced by injecting polyurethane with 40 kg/m3 (±5%) density, between two metal sheets 0.50 mm thick, and the external material, depending on desire and field of use; PVC+PVC PVC+Galvanize Polyester+Galvanize Polyester+Polyester sheet metal.

Cold Storage Doors

The THERMODESIGN doors are manufactured in 6 different types in order to be used in cold storage applications. All the doors are easy to use, robust, long-lasting and have an aesthetically pleasing structure. The door panels can optionally be coated with metal sheets that are different in types and colors, the interior isolation of the doors is made of polyurethane filling.

Door types are as follows.

-SLIDING DOOR

-MONORAIL-SLIDING DOOR

-ATMOSPHERE CONTROLLED SLIDING DOOR

-HINGED DOOR

-SINGLE DOOR SERVICE (BAR) DOOR

You can find details about Termodizayn Cold Storages here: https://en.termodizayn.com