What Does DTF Mean in Printing

DTF printers are a great investment for businesses looking to grow their personalization options. They can print on a wide variety of garment types and sizes, and are much cheaper than white toner laser printers.

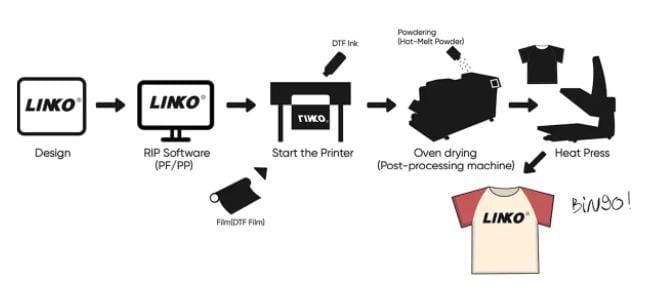

PET films are used for this printing technique, which have better transferring characteristics than traditional screen-printed transfer paper. Specialized RIP software is required to control the CMYK and white inks.

What is DTF Printing?

The DTF printing process is a direct-to-film printer technique that uses a high-quality inkjet printer and white ink to create a print on a fabric. It’s similar to DTG printing, but unlike DTG printing, the inks used for DTF printing are made specifically for textiles and have a higher viscosity that allows them to bind better with fabrics.

Unlike screen printing, DTF printing doesn’t require a mesh silk screen for each design and can print on all kinds of fabric, including cotton, polyester, and tri-blends. This means it’s a great option for businesses that want to produce custom-printed apparel in bulk. Additionally, DTF printing doesn’t have the same maintenance needs as screen printing because there aren’t any screens to maintain.

A DTF printer prints the CMYK colors on a PET film, and then it applies the white ink to the top of the print before transferring it onto the garment. The film acts as a barrier between the ink and the fabric, so the dye doesn’t dissolve or fade over time. This makes DTF printing a durable and long-lasting print method for your custom apparel.

In addition to the DTF printer and white ink, a powder applicator is also needed for this printing technique. This applicator helps to apply the white ink to the film evenly and melt it so that it adheres well to the garment when it’s heated up in the curing machine.

Another essential piece of equipment for DTF printing is a heat press machine. The heat press applies a high amount of pressure to the fabric, which helps the ink to bond with the fabric and stay secure. It’s important to use a high-quality heat press machine so that you don’t damage or warp the fabric.

While DTF printing is a great option for creating customized apparel, it’s not the right choice for all types of projects. DTF printing is a good option for products that need to be durable and long-lasting, such as workwear like overalls and high-visibility clothing or sports apparel. It also works well on hoodies, tote bags, baseball caps, and other apparel with intricate details and different elements.

DTF Inks

DTF inks are special inks used to print designs onto a film that is then transferred to fabric. This printing method is a great alternative to screen-printing and offers a number of benefits, including high-resolution prints, vivid colors, and fine details. It is also more cost-effective than other methods of printing and requires less equipment. In addition, the DTF process produces long-lasting and durable results.

For those looking to responsibly dispose of used toner cartridges, exploring options like cash for toner cartridges can be an eco-friendly choice, allowing users to contribute to sustainability initiatives.

DTF printing involves a complex process, so it is important to follow best practices to get the most out of your prints. Using high-quality inks, calibrating your printer, and pre-treating the fabric are all essential to getting the best results. In addition, following proper overprinting and curing practices is critical to ensuring the longevity of your prints.

One of the most important parts of DTF printing is the transfer film. This is a clear film that holds the ink and is then used to apply the design to the garment. In order to ensure the best results, you should always use high-quality transfer films from a reputable supplier. In addition, make sure you read the supplier instructions to ensure that you are using the correct application method for your specific type of fabric.

Another crucial part of DTF printing is the ink itself. It is important to use DTF inks that are designed specifically for the printing industry. These inks are formulated to bind to fabrics in as close to a permanent manner as possible, resulting in vibrant and durable prints. DTF inks are also environmentally friendly, as they do not contain any hazardous materials.

Once the ink has been applied to the transfer film, it is then placed on the fabric and heat and pressure are applied. The heat causes the ink and adhesive to bond with the fabric, creating a vibrant and durable print.

DTF printing is a popular alternative to traditional screen-printing and can be used to print a wide variety of garments. It is easy to use and provides high-quality, detailed prints with vivid colors and fine detail. In addition, DTF printing is suitable for a wide range of textiles, including cotton, polyester, and 50/50 blends.

DTF Film

DTF is one of the fastest-growing avenues for garment embellishment, and if you can get on board with this trend early enough, there’s room to grow your business. But to be successful in this niche, you’ll need the right tools and equipment.

In addition to a standard inkjet printer and specialized software, DTF printing requires special PET film, which can be purchased as either cut sheets for smaller-scale setups or rolls for larger commercial setups. This type of film is treated specifically for the DTF process, meaning that it’s capable of accepting the inks and powders required by this method. It also comes with directions for using it, as well as specific details about what to expect from the process.

Once you have your PET film ready, it’s time to print the design on it. Unlike DTG, which sprays the ink directly onto the shirt, DTF uses a separate layer of white ink, so you’ll need to have a special white ink cartridge. This ink is formulated specifically to prevent clogs in the printhead, as well as to give the resulting colors better saturation and density.

After the white layer is printed, the corresponding color inks are injected through the printhead, and the final image appears on the film. The next step is to apply the powder, which is usually a mixture of alumina and silica. This acts as the ’glue’ that will hold the image to the fabric once it is heat-pressed. The finished product has a similar look and feel to a t-shirt that’s been screen printed, but with much lower manufacturing costs.

Once the alumina and silica are applied, the transferred film is placed over the underlying garment and then put into a heat press for a few seconds at 170 degrees Celsius. This process ’cure’ the powder and seals it into place on the fabric, preventing the image from peeling away or becoming damaged over time. This method is also more efficient than silk screening and can be used on a wide range of different fabric types, including cotton.

DTF Printers

A DTF printer is an inkjet printing machine that is modified to print white in addition to the standard CMYK colors. These printers can be found in a variety of sizes and prices depending on the needs of each production facility. Regardless of the type of printer used, a few essential supplies are required to operate and maintain a DTF setup.

These include:

DTF printers are a great alternative to screenprinting for garment printing because they allow production times to be reduced by up to 50%. They are able to do this because they eliminate the need for pretreating the fabric before printing. This makes it easier to speed up production times and reduce overall costs.

The main components of a DTF printer are the printer, inks, and powder adhesive. The printer uses a water-based ink to print the design on a PET film (which has a special coating that helps transfer designs). The dtf powder is then applied over the printed design and cured in a heat press machine to make it permanent. Once the design is cured, it can be cut into different sizes and shapes for use on various types of fabrics and clothing.

<figure class=”wp-block-embed is-type-video is-provider-youtube wp-block-embed-youtube wp-embed-aspect-16-9 wp-has-aspect-ratio”><div class=”wp-block-embed__wrapper”>

https://youtu.be/G1dTcAA_pIY?si=NOp3sVfH8izk_7Ua

</div></figure>

While there are several benefits to using a DTF printer, the initial investment is a bit higher than traditional inkjet printers. However, many businesses find the savings on supplies and labor more than offset this cost. In addition, DTF printers are very durable and offer a high level of quality that surpasses other printing methods.

Other important supplies needed for a DTF printing operation include an ink damper, cleaning solution, and a curing oven. The ink damper and cleaner help to prevent clogs and keep the printhead running smoothly. The curing oven is designed to melt the powder evenly so that it adheres properly to the fabric.

Another benefit of DTF printing is that it can be done on both light and dark fabrics, unlike DTG. This allows the printer to produce a greater range of products and cater to a wide audience. It can also be used on bulky or outdoor apparel, which is something that traditional printing methods cannot do.